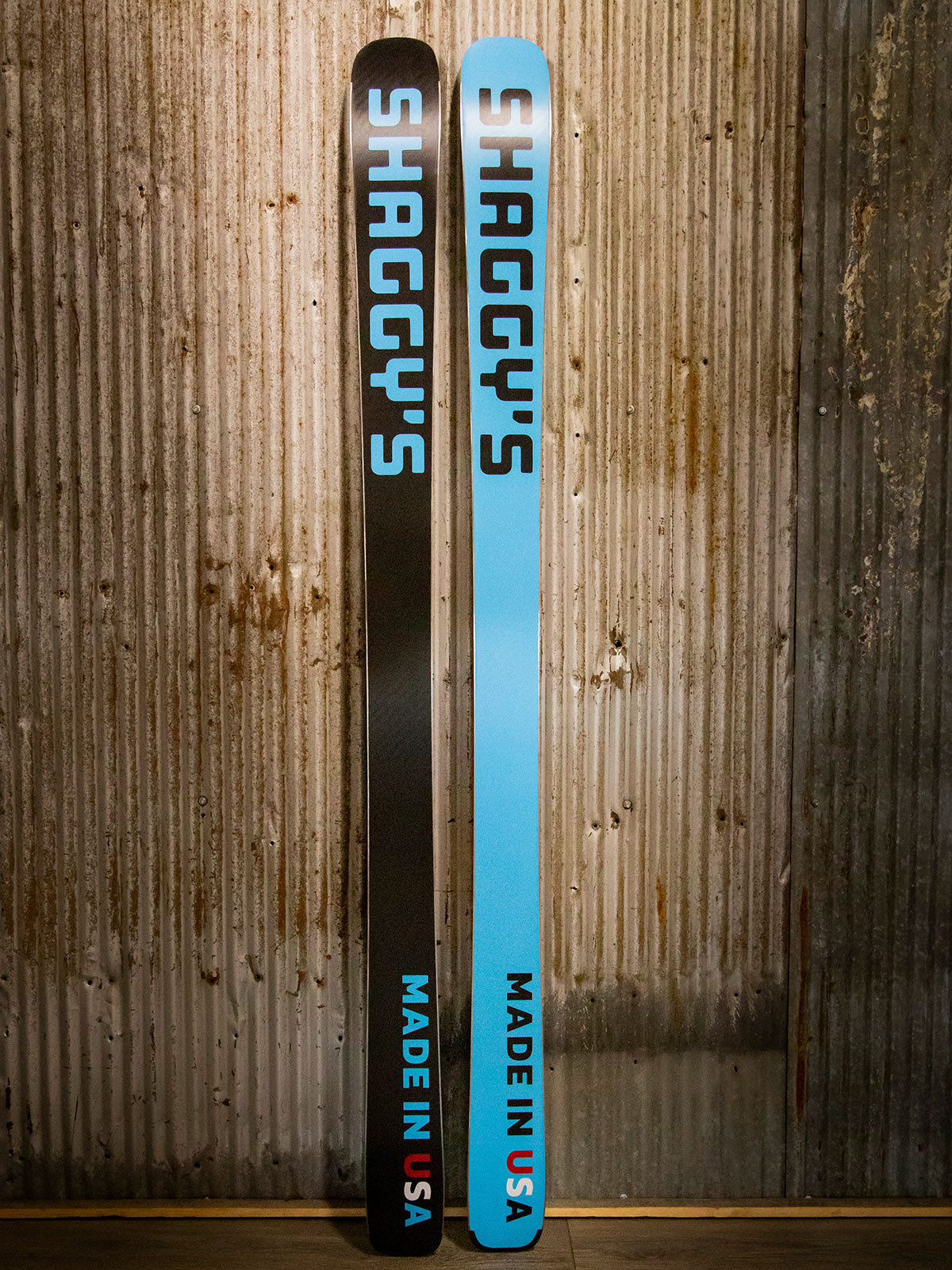

Limited Edition America! Skis

Get your spot in the build queue now!

HOW IT WORKS:

- Order your new skis and we handcraft a pair just for you

- You can order both stock and custom skis

- Skis ship by the ship by date listed on the product page

HAVE QUESTIONS?

Phone: 231-459-4323

Email: mail@skishaggys.com

Why Do I have to Wait?

- Every pair of skis is custom built, whether you add a custom option or not, we use the exact same build process in every pair. It takes time to carefully craft each pair. We don’t cut corners, only the best - no compromises.

- Custom skis can take time to complete artwork and design, so order early!

- Our ski build queue is currently at our production capacity and quality takes time

When should I expect my skis?

- Your skis will ship based on the current Build Time/Ship By date listed on the product page.

- Once your skis are ready to ship, we'll email you a tracking number with an estimated delivery date. Most orders ship via USPS Priority Mail.

Want skis faster?

- Contact us to see if we can expedite your order.

Phone: 231-459-4323

Email: mail@skishaggys.com - Contact us to see what we have in stock - we often have pre-built custom skis available that are not listed online.

Customer Photos

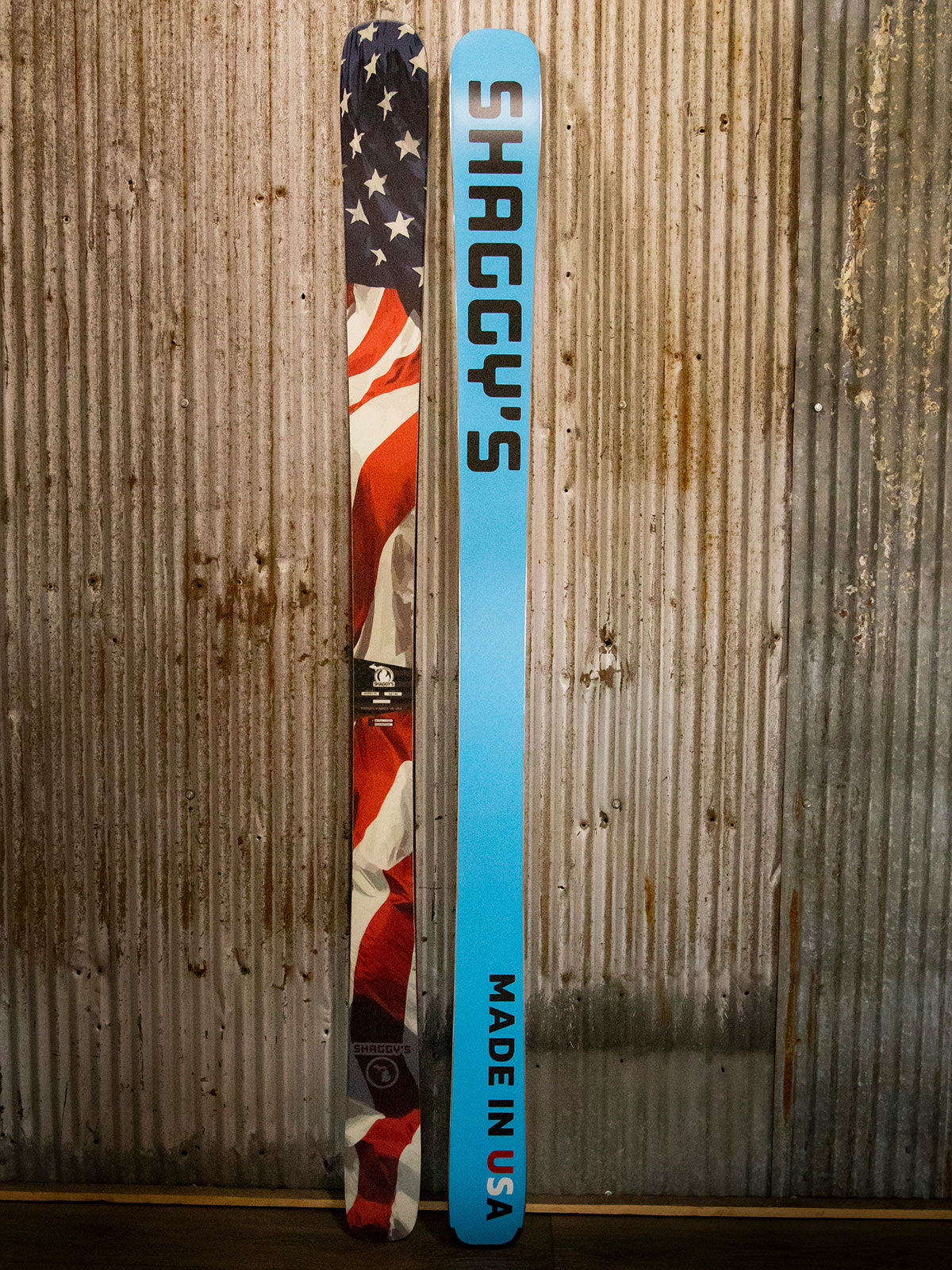

Limited Edition America! Skis

Limited Build Quantity: 100 Pair

Shape: Any model we make

Details

These new America! Limited Edition Skis show our love of crafting skis in our own small factory, right here in the USA. We build every pair of skis with the best materials and are hands on with every pair. We do if for the love of skiing and hope our passion is passed on with every pair sold!

We're only building a total of 100 pairs of skis with the America! Limited Edition graphic. Once they're sold out, this graphic is gone for good! This limited edition graphic is available on any ski model that we make - from our narrowest, ice-friendly Brockway 80, to our adventurous Ahmeek 105, and even our dedicated powder skis like the Tubby 120. Choose the ski model that best fists your style, and if you need help picking the perfect pair, just fill out our ski recommendation form.

- Custom American Flag topsheet shows your patriotism and stands out on the slopes.

- Custom red, white, and blue base letters die cut into race-grade 4001 Durasurf UHMW ski base.

- Available on any model to suit your unique skiing style.

- Custom built on demand - built just for you, not the masses.

Common Questions

What ski model should I get?

Each ski model is made for a specific set of snow conditions and skier style. Read about each model at www.skishaggys.com/collections/2021-2022-skis.

Want a recommendation? Fill out the form at www.skishaggys.com/pages/help-me-find-skis or give us a call at 231-459-4323.

What length should I get?

Ski length should be chosen based on your selected model, ability, and your preferred terrain. Check out our size chart for more info, or we're happy to give you a recommendation!

What bindings should I get?

You can use any binding on these skis as long as the brake width is at least equal to the waist width of the skis. For example, if you purchase the Belle 90 model, you'll need a brake width of at least 90 mm. We run Marker Griffon and Marker Squire bindings on our demo skis. Visit your local ski shop for bindings and mounting.

What can I customize?

Just about anything!

Build your own custom pair at www.skishaggys.com/products/custom-skis

See all the options at www.skishaggys.com/pages/custom-skis

Have questions? Get a consultation

What are Camber Pockets?

Camber Pockets are additional small sections of camber (about 4" long and 0.030" tall) molded into the overall camber of the ski in front of and behind your midsole position. They increase contact pressure to improve grip on hardpack and ice.

Are they tuned and waxed?

Skis come tuned with a 1° base edge bevel and a 2° side edge bevel and a slight tip/tail detune. The skis are waxed with a universal temperature wax to get you going.

rowtype::double_block

imageside_filename::test1.jpg

imageside::left

rowcolor::white

rowwidth::full

rowpadding::none_none

rowcontent::

Premium Materials

Core

Laminated ash/poplar hardwood: Long grain premium white ash and tulip poplar is hand selected and cut into full-length strips. Strips are individually flex indexed and laminated together symmetrically. Each laminated core is CNC milled to a precise thickness profile developed for each model and length.

Composites

Unidirectional carbon fiber strips below the core, lightweight triaxial fiberglass above and below the core, fiberglass binding mat underfoot. Rubber bonding strips placed along edges, sidewalls, and ends for rock-solid bonding.

Bio-Based Epoxy

Entropy Super Sap® epoxy contains 28% bio-based content and is specifically designed for skis. It's formulated for high strength and impact resistance, which creates a durable, tough, and lightweight composite.

Sidewall

Full-height urethane - bombproof and double-chamfered for reduced swing weight. A rounded mini-cap top edge rolls over the sidewall to protect your topsheets.

Topsheet

Clearview nylon protects the sublimated graphics on the inside of the material.

Base + Edge

1.4 mm CNC knife-cut 4001 Race Grade Durasurf sintered UHMW. 2.2 mm oversized and heat-treated edges take a beating.

rowtype::double_block

imageside_filename::Inspecting_Skis.jpg

imageside::right

rowcolor::white

rowwidth::full

rowpadding::none_none

rowcontent::

Why Shaggy's?

Every single pair of Shaggy’s is built at our small, wholly-owned ski factory in Boyne City, Michigan. We source all of our materials as locally as possible and take no shortcuts during the build process, using the most modern equipment and methods to carefully craft our skis.

Cutting-edge technology, premium materials, and limitless customization are worthless if the end product isn’t built with passion. A love for skiing is a prerequisite for each and every employee at Shaggy’s. We design, prototype, and test every ski model before it’s made available to you, and that passion for skiing is clearly evident in our end product.

That exacting detail doesn’t end with your new skis; your experience as a customer is paramount to us as well. Our team is always happy to offer assistance - before, during, and after your ski purchase. Find out for yourself why we refer to our customers as the Shaggy’s Family.

rowcolor::gray

rowpadding:small_small

rowwidth::full

rowtype::covet

rowcontent::62700

rowcolor::gray

rowpadding::small_large

rowwidth::page

rowtype::judge_me

Common Questions

What length should I get?

What bindings should I get?

What can I customize?

Just about anything from graphics to construction!

Build your own custom pair at www.skishaggys.com/products/custom-skis

See all the options at www.skishaggys.com/pages/custom-skis

Have Questions? Get a consultation

Are they tuned and waxed?

Skis come tuned with a 1° base edge bevel and a 2° side edge bevel and a slight tip/tail detune. The skis are waxed with a universal temperature wax to get you going.