Limited Edition Lake Superior V3 Skis

Get your spot in the build queue now!

HOW IT WORKS:

- Order your new skis and we handcraft a pair just for you

- You can order both stock and custom skis

- Skis ship by the ship by date listed on the product page

HAVE QUESTIONS?

Phone: 231-459-4323

Email: mail@skishaggys.com

Why Do I have to Wait?

- Every pair of skis is custom built, whether you add a custom option or not, we use the exact same build process in every pair. It takes time to carefully craft each pair. We don’t cut corners, only the best - no compromises.

- Custom skis can take time to complete artwork and design, so order early!

- Our ski build queue is currently at our production capacity and quality takes time

When should I expect my skis?

- Your skis will ship based on the current Build Time/Ship By date listed on the product page.

- Once your skis are ready to ship, we'll email you a tracking number with an estimated delivery date. Most orders ship via USPS Priority Mail.

Want skis faster?

- Contact us to see if we can expedite your order.

Phone: 231-459-4323

Email: mail@skishaggys.com - Contact us to see what we have in stock - we often have pre-built custom skis available that are not listed online.

Customer Photos

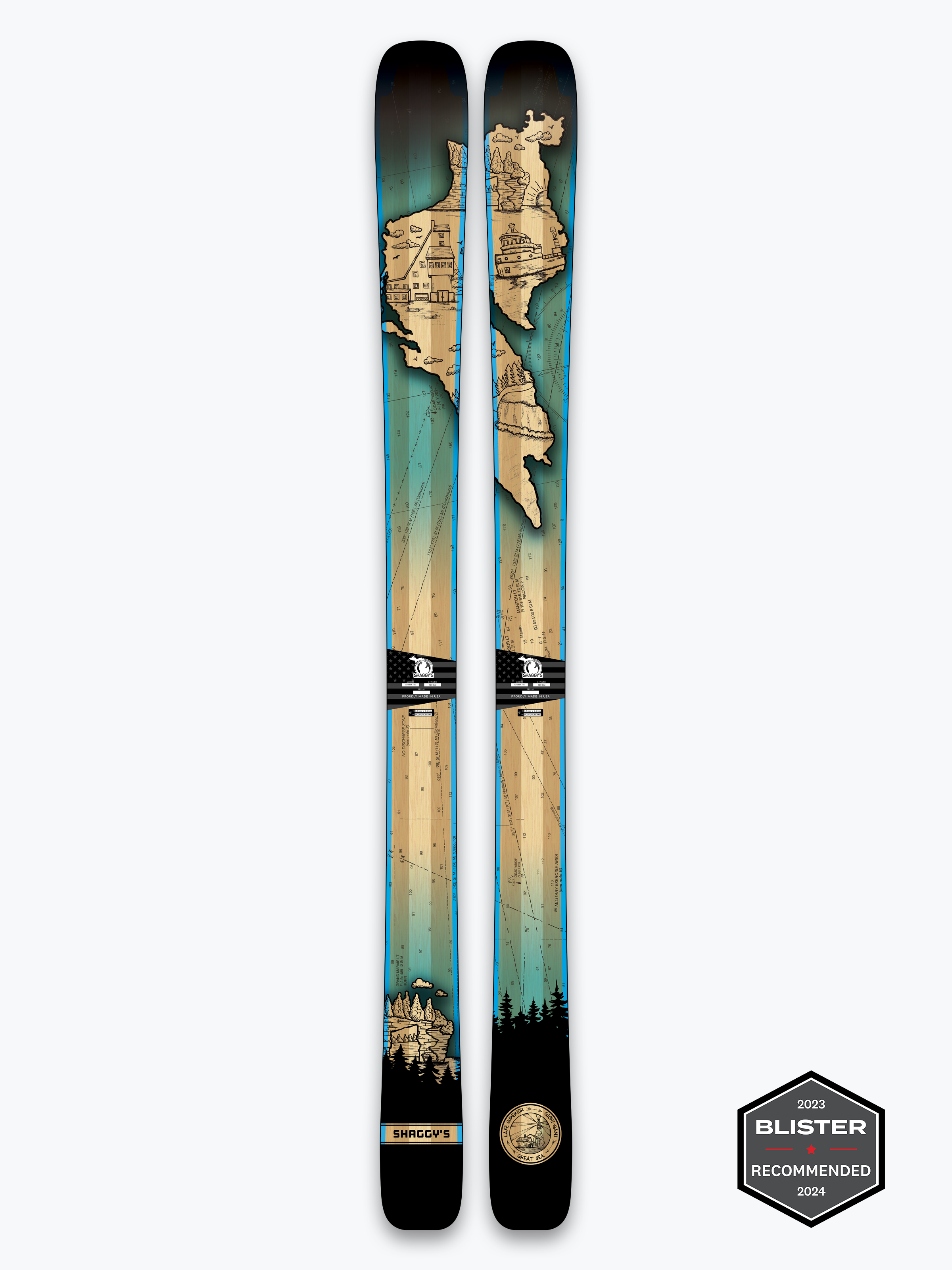

Limited Edition Lake Superior V3 Skis

Inspiration

Lake Superior is incredible to behold. The Pictured Rocks National Lakeshore is like something out of a dream. The crystal-clear water and ominous rocky cliffs are one of the natural wonders of the Midwest. These skis feature some of the most iconic landmarks of Lake Superior. These landmarks are captured through artwork illustrated by our artist, Sean, for these limited-edition skis. The wood core of the skis shows through the topsheet giving these skis an aesthetic that is as cool as the Lake Superior water.

Details

This Limited Edition Lake Superior Graphic is available on most skis in our lineup. Some skis are not listed as available on this page due to materials on top of the wood core (Brockway line, Mohawk 98, Fun Carver 88), if you are interested in seeing what those would look like, please contact us.

Need help choosing the right model? Just give us a call at 231.459.4323 or live chat below for some expert advice from a ski builder!

Features

- Custom built - each pair built just for you

-

Real wood - you're seeing the actual construction of the ski

- Available on most ski models - to suit your unique skiing style

Common Questions

What length should I get?

What bindings should I get?

What can I customize?

Just about anything from graphics to construction!

Build your own custom pair at www.skishaggys.com/products/custom-skis

See all the options at www.skishaggys.com/pages/custom-skis

Have Questions? Get a consultation

Are they tuned and waxed?

Skis come tuned with a 1° base edge bevel and a 2° side edge bevel and a slight tip/tail detune. The skis are waxed with a universal temperature wax to get you going.

Core

Laminated ash/poplar hardwood: Long grain premium white ash and tulip poplar is hand selected and cut into full-length strips. Strips are individually flex indexed and laminated together symmetrically. Each laminated core is CNC milled to a precise thickness profile developed for each model and length.

Composites

Unidirectional carbon fiber strips below the core, lightweight triaxial fiberglass below the core, fiberglass binding mat underfoot. Rubber bonding strips placed along edges, sidewalls, and ends for rock solid bonding.

Bio-Based Epoxy

Entropy Super Sap® epoxy contains 28% bio-based content and is specifically designed for skis. It's formulated for high-strength and impact resistance, which creates a durable, tough, and lightweight composite.

Bio-Based Urethane Sidewalls

Full-height Urethane sidewalls contain at least 25% bio-based content, partially derived from coconuts! This eco-friendly construction method reduces plastic sidewall waste by at least 60% without compromising on quality. A rounded mini-cap top edge rolls over the sidewall to protect your topsheets.

Topsheet

Clearview gloss nylon with sublimated graphics and transparent windows to the wood core.

Base + Edge

1.4 mm CNC Knife Cut 4001 Race Grade Durasurf sintered UHMW. 2.2 mm over-sized and heat treated edges take a beating.